Dongcheng Science and Technology Park,Dongcheng District,Dongguan City,Guangdong Province,China

Frequently Asked Questions

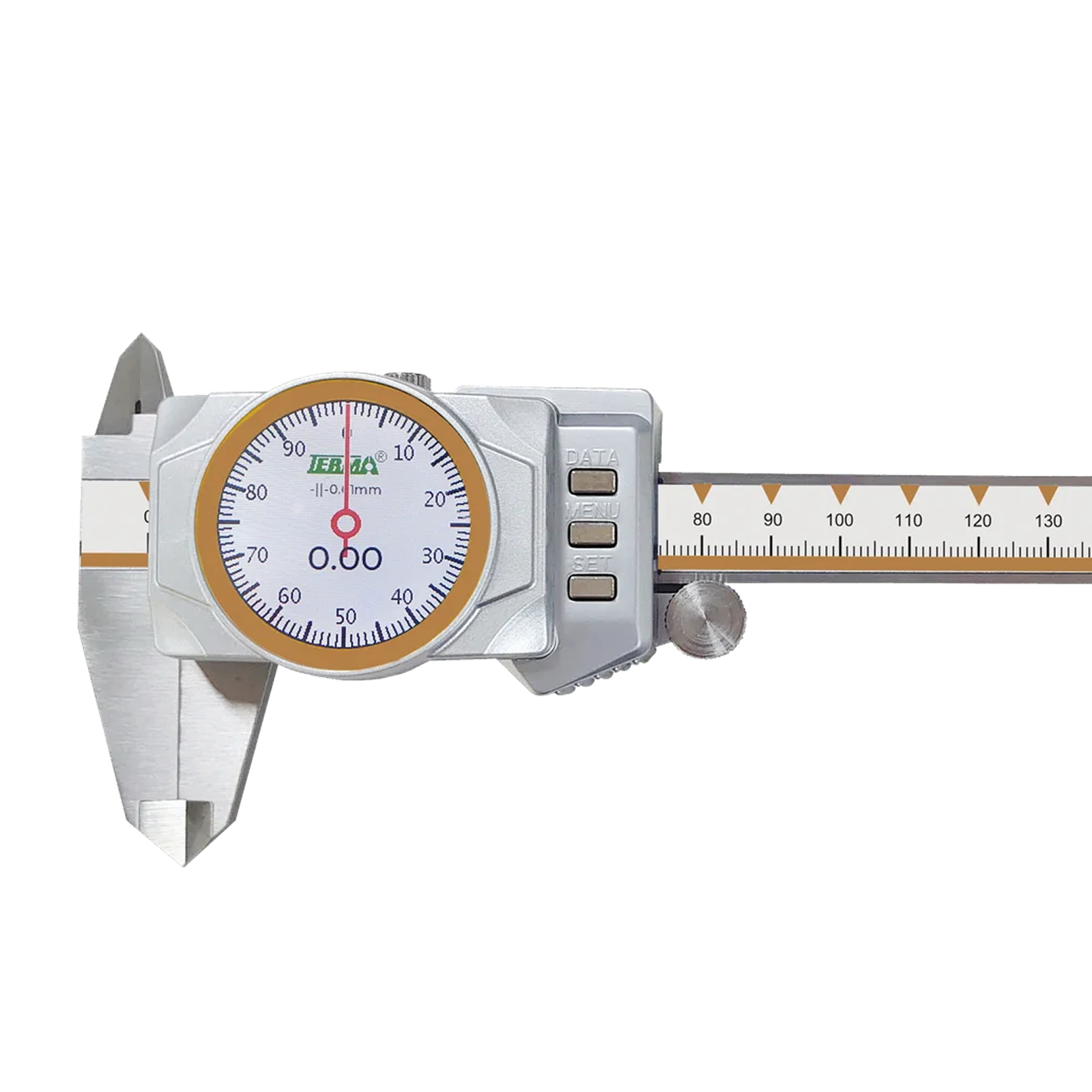

Caliper is suitable for wider measuring range and versatile measurements such as inside-outside diameter, depth. Micrometer is designed for more precise measurements (usually 0.01 mm or smaller), but its measuring range is more limited. Micrometer is preferred for critical measurements that require precision, while caliper is used for more general or large-sized measurements.

Standard reference blocks (gauge blocks) or calibration plates are used for calibration. The measuring device must be zeroed, then the accuracy of the device is tested by taking measurements at different height and depth points. Periodic calibration prevents measurement errors and ensures compliance with occupational safety standards.

The surface of the digital watercress must be clean and dry, and the device must be protected against vibration and impact. The surface to be measured must be flat and properly supported. The battery status of the device must be checked and regular calibration must be performed. For work safety, the user must wear gloves and precautions must be taken against the device falling.

The most common errors include incorrect assembly, uncleanliness of the measuring surface, failure to zero the instrument, and excessive force. These errors can lead to incorrect results and equipment damage. Before measuring, the instrument must be cleaned, correctly assembled, and zeroed.

When choosing a scale, your intended use, measurement accuracy, durability and material are important criteria. Scales are available in metal, plastic or digital versions. Selecting the appropriate material for the conditions of the measurement environment (humidity, temperature, chemical effects) is critical for occupational safety and long life.